PRODUCT CENTER

Our products mainly include ferrosilicon alloy, ferromanganese alloy, manganese silicon alloy, metal manganese, metal silicon, ferrochrome, ferrotitanium, ferromolybdenum, ferrovanadium and other alloy products, which can be customized according to customer requirements.

Electrolytic Manganese Flakes 99.8

According to the industry standard YB/T051-2003 "Electrolytic Manganese Metal", electrolytic manganese metal is divided into four grades. Table 1 Grades and chemical composition of electrolytic manganese metal

Electrolytic Manganese Flakes 99.9

According to the industry standard YB/T051-2003 "Electrolytic Manganese Metal", electrolytic manganese metal is divided into four grades. Table 1 Grades and chemical composition of electrolytic manganese metal

Manganese metal is divided into various grades according to purity, use and production process. The main distinction standards include international standards (such as ISO, ASTM)

Manganese metal is divided into various grades according to purity, use and production process. The main distinction standards include international standards (such as ISO, ASTM)

The role of molybdenum in steel can be summarized as improving hardenability, improving thermal strength, preventing temper brittleness, improving remanence and coercivity, and corrosion resistance in certain media, and preventing pitting corrosion. Due to the various beneficial effects of molybdenum in steel,it has been widely used in a series of steel grades such as structural steel, spring steel, bearing steel, tool steel, stainless acid-resistant steel, heat-resistant steel (also known as heat-strength steel), and magnetic steel. Molybdenum is very effective in improving strength and toughness in cast iron. When the addition amount is 0.25% to 1.25%, it can also form pearlite matrix structure for castings with medium and large sections. Commonly used in rolls and other wear-resistant castings.

Among these uses, the steelmaking, foundry and ferroalloy industries are users of ferrosilicon. Together they consume about 90% of the ferrosilicon. Among various grades of ferrosilicon, 75% ferrosilicon is widely used at present. In the steelmaking industry, 3-5 kg of 75% ferrosilicon is consumed per ton of steel produced.

Silicon manganese alloy is used for steelmaking. The melting points of the deoxidized products MnSiO₃ and Mn₂SiO₄ are 1270°C and 1327°C respectively. They have the advantages of low melting point, large particle size, easy floating, and good deoxidation effect. Specifications and particle size: natural block, 10-100mm, powder or customized according to customer requirements. Packaging: one metric ton in a large bag, or according to customer requirements

Steel industry: Ferromanganese is an indispensable deoxidizer and desulfurizer in the steelmaking industry. Good steel needs to be deoxidized and desulfurized during smelting, and the use of deoxidizers will greatly increase its cost. Therefore, ferromanganese is a cheap deoxidizer. Desulfurization refers to the removal of harmful substances such as sulfur in steel. ferromanganese can well achieve the purpose of desulfurization, effectively reduce the content of harmful elements in steel, and improve the quality of steel.

Experience

Active Employees

Floor Area

Cooperative Partner

TAIGANG TONGCHUANG WUXI METAL PRODUCTS CO., LTD

Taigang Tongchuang Wuxi Metal products Co., LTD is an alloy products enterprise integrating production, supply, sales and export. Our products mainly include ferrosilicon alloy, ferromanganese alloy, manganese silicon alloy, metal manganese, metal silicon, ferrochrome, ferrotitanium, ferromolybdenum, ferrovanadium and other alloy products, which can be customized according to customer requirements. We put customer satisfaction first and produce strictly in accordance with customer requirements.

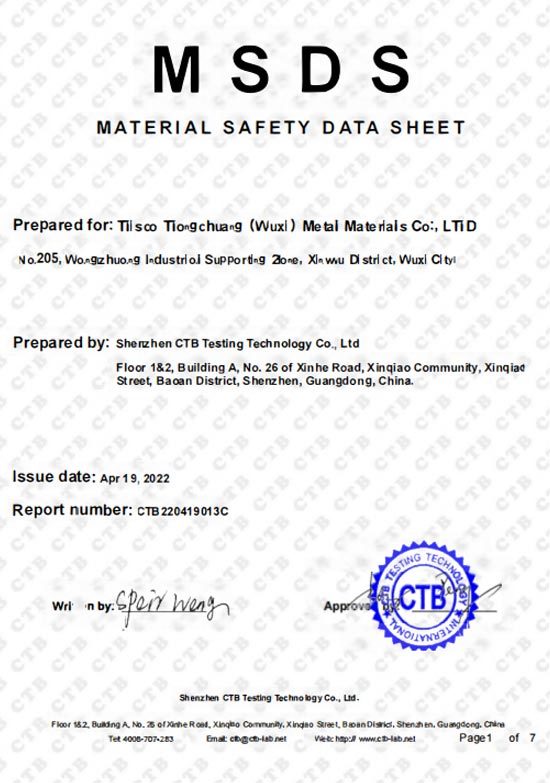

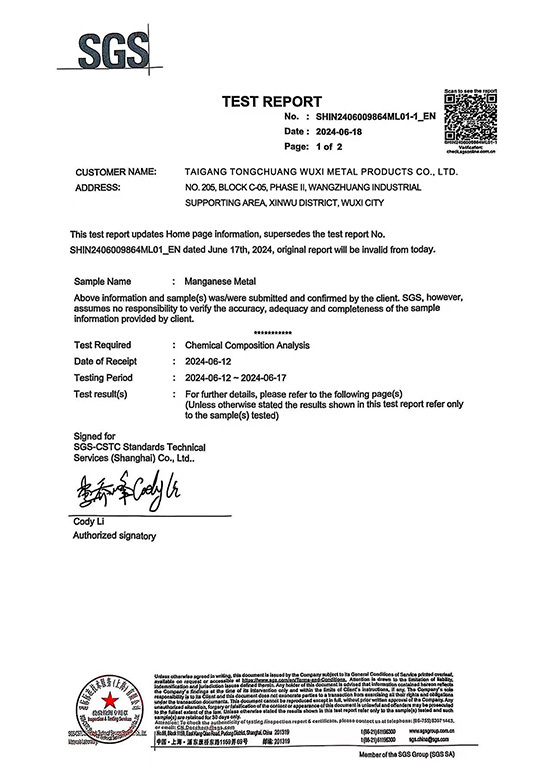

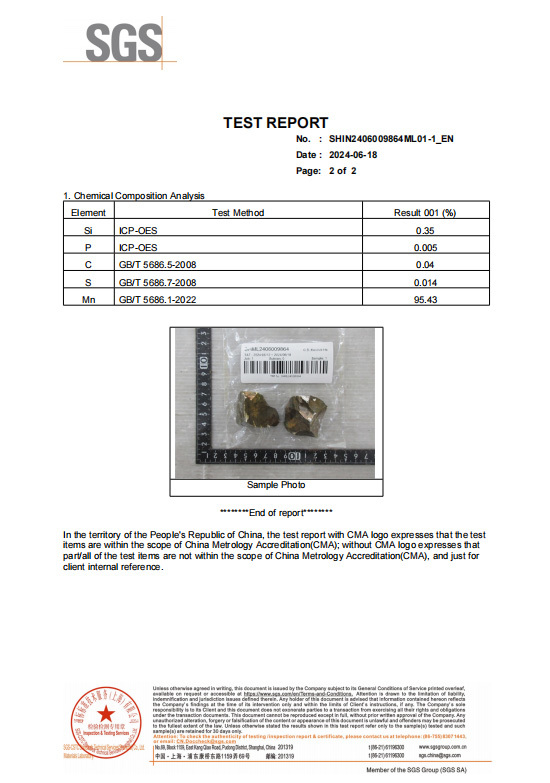

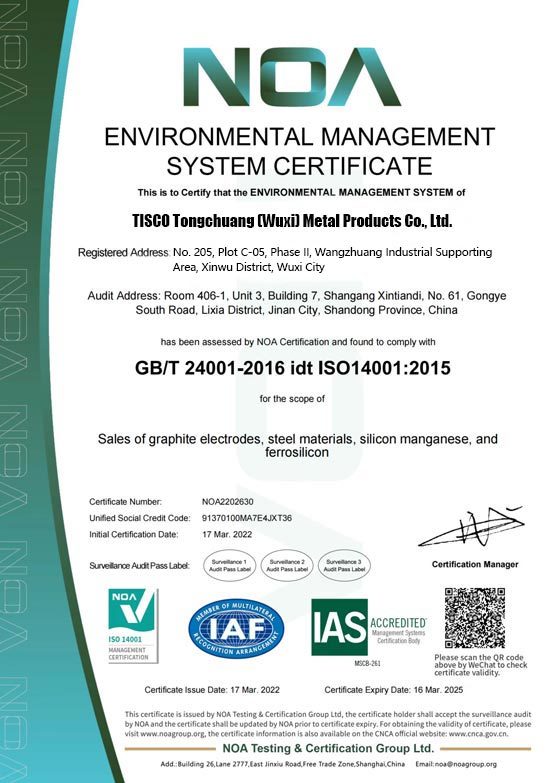

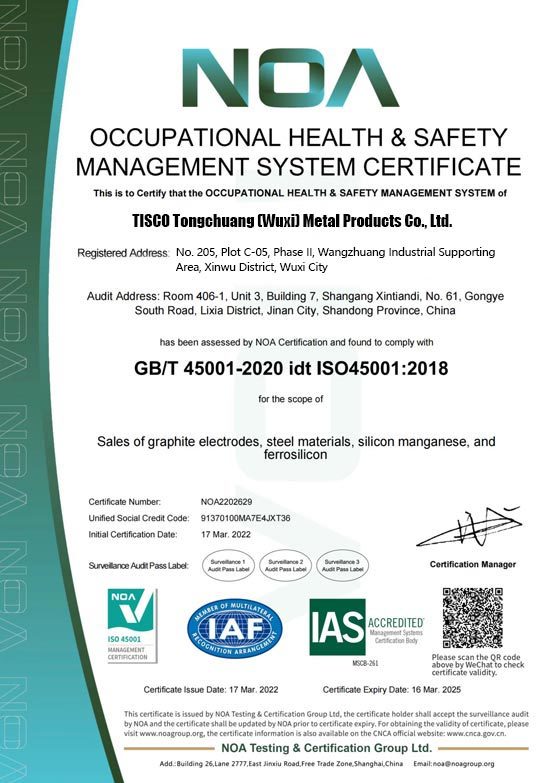

CERTIFICATE

IRON ORE MINING

Iron ore mining

Boiler Production

Finished Product Display

Ton Bag

Container Loading

Shipping Worldwide

NEWS CENTER

The relationship between iron ore and steel

The relationship between iron ore and steel is closely related and mutually restricted, and the two together form the core of the steel industry chain. Understanding this relationship will help better grasp the development trends and market trends of the steel industry, and provide important reference for the strategic decisions of related companies.

The difference between iron ore and iron meteorite

Iron Meteorite: Because of its rarity and scientific research value, it is mainly used for research and collection, and some cultures have used it to make tools and weapons.

03-26

2025

Is iron ore an alloy?

Iron ore is a natural mineral resource, mainly used for smelting metal iron, but it does not have the composition and characteristics of alloys themselves. Therefore, iron ore does not belong to alloys.

03-26

2025

How is iron ore formed

The formation of iron ore is the result of the combined action of multiple geological actions, including the enrichment, oxidation and deposition of iron elements, weathering and transport, as well as crustal movement and metamorphosis. Together, these processes have created the rich iron ore resources on the earth and provided important raw materials for modern industry.

03-26

2025

Density of iron ore

The density of iron ore is affected by its grade and crystallization condition. For example, the density of iron ore with a grade of about 30% is about 4.8 T/m³.

03-26

2025

Uses of iron ore

The uses of iron ore are mainly concentrated in steel production and its derivative fields. Its quality and characteristics directly affect the performance of steel, and thus have a profound impact on many industries such as construction, machinery manufacturing, automobiles, ships, and energy.